Capacity Management

Secure your suppliers feasibility to deliver by collaborative capacity management

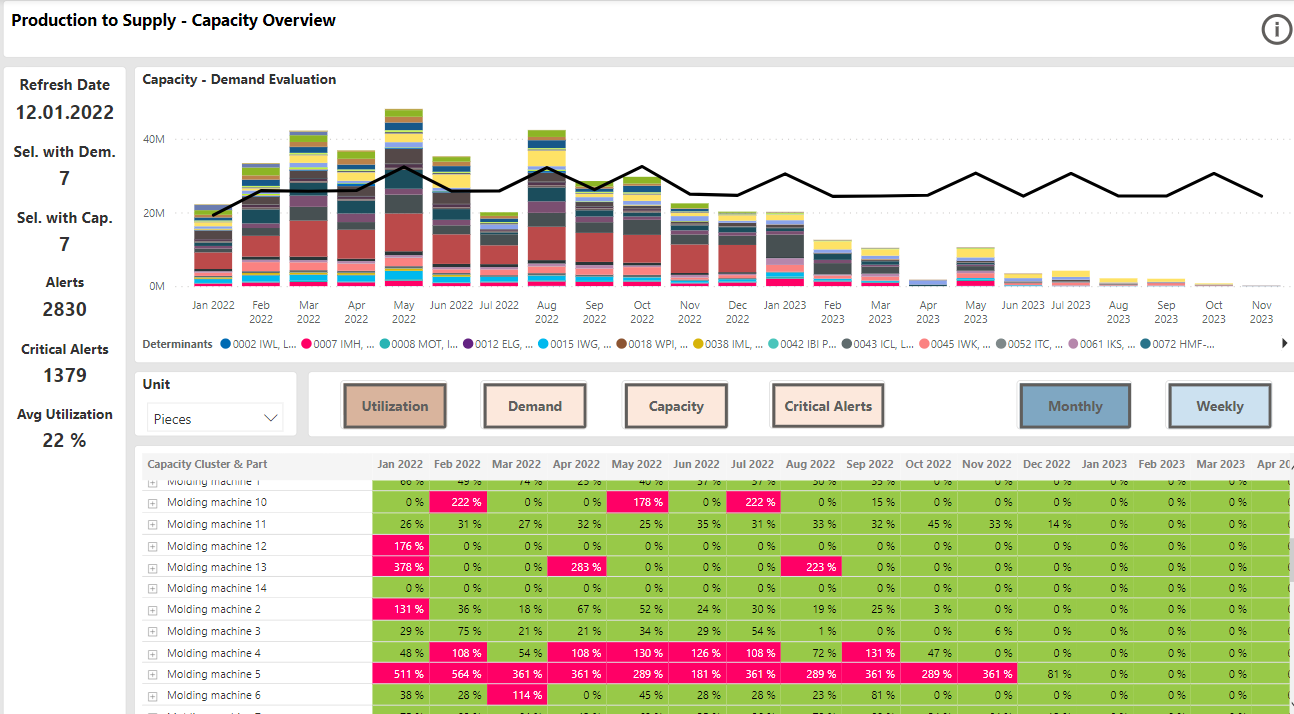

SupplyOn Capacity Management continuously shows your suppliers your future demands and compares them with the committed capacities.

In addition, sales fluctuations and product lifecycle changes are displayed and mirrored with your supplier network. Intelligent alerts inform you about possible deviations or disruptions so that you can take countermeasures well in advance. Supply bottlenecks in your supplier network and the related disruptions of your production can thus be optimally prevented. The transfer of data to your S&OP plan ensures smooth planning and secures your own supply capability.

Key features:

- Flexible definition of planning levels: Parts, Part Families, Bottleneck Clusters, Machine Capacities

- Flexible customer integration: API based data integration, SCM/eSCM based data, S&OP based data

- Dynamic alerts in case of discrepancies between demand and committed capacities

Your benefits:

- Long-term assurance of supply capacities for critical materials

- Reduced risk of production downtime due to lack of purchased parts

- Validation of your S&OP planning with your supplier

- Reduction of lead times and planning cycles by up to 20%

- Reduction of process costs by up to 30% through automation of manual capacity adjustments

Resources: