Production Progress and Stock Monitoring

Visibility and integration of manufacturing data from your suppliers

Especially for complex manufacturing process with long running production orders, lack of lack of visibility about production status and timely delivery causing large operational efforts, escalation processes and costs.

By integrating data from the supplier's manufacturing (machine data, OEE, FYD) into the ordering and delivery process, valuable insights into the current state of production are created - for both the supplier and the customer. This means that production planning can be continuously optimized on both the supplier and customer sides, resulting in significant savings in terms of costs and time.

Key features:

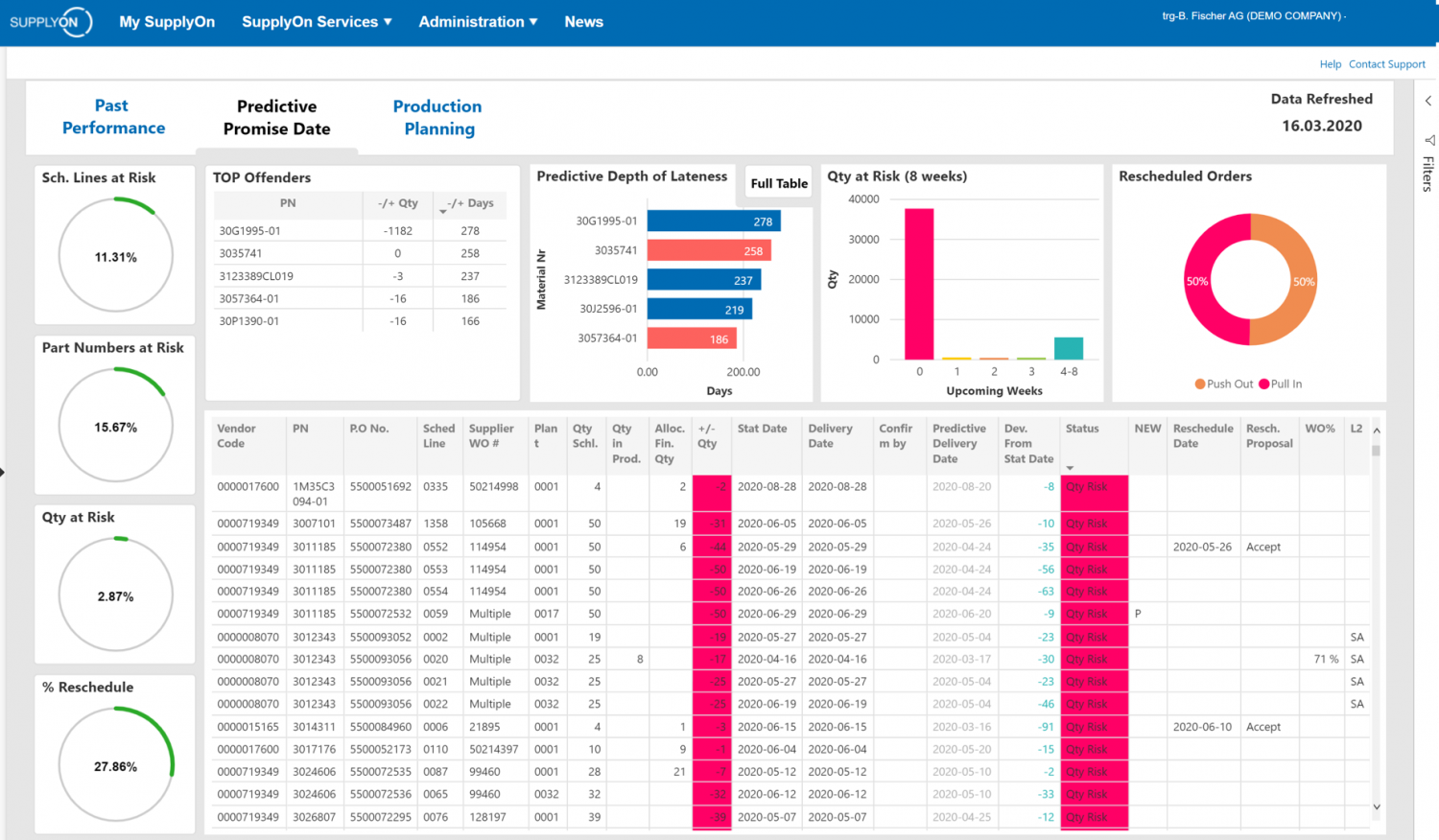

- Detailed insight into the production progress at the supplier's site e.g. on work orders, production progress, stock levels and replenishment situation

- Machine-learning-based algorithms improve forecasting

- Flexible integration of manufacturing data (machine data, OEE, FYD)

Your benefits:

- Visibility on long running production processes of your suppliers

- Improved production capacity utilization leads to savings of up to 20 percent

- Quick identification of production problems at the supplier allow prompt mitigation countermeasures

- Intelligent forecasts predict potential delivery delays long before they occur

Contact for demo